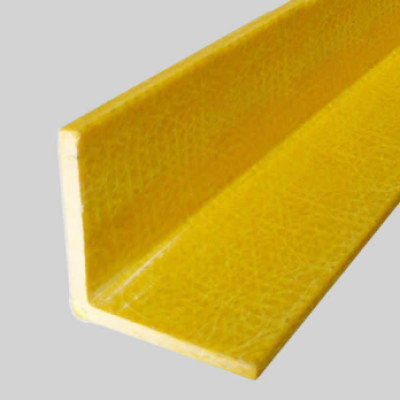

GRP Pultruded Profiles

GRP Pultruded Profiles refer to a specific method of manufacturing Glass Fiber Reinforced Polymer components. The term pultrusion refers to a process where continuous strands of glass fibers are impregnated with a resin matrix, and then pulled through a heated die to form a specific profile or shape.

Key Characteristics of GRP Pultruded Profiles:

- High Strength-to-Weight Ratio: Pultruded FRC profiles are incredibly strong yet lightweight, making them easy to handle, transport, and install. The glass fibers provide tensile strength, while the concrete matrix provides compressive strength.

- Durability and Longevity: These profiles are resistant to environmental factors such as corrosion, moisture, and UV degradation. Pultrusion technology ensures that the glass fibers are evenly distributed, which contributes to the overall durability of the product.

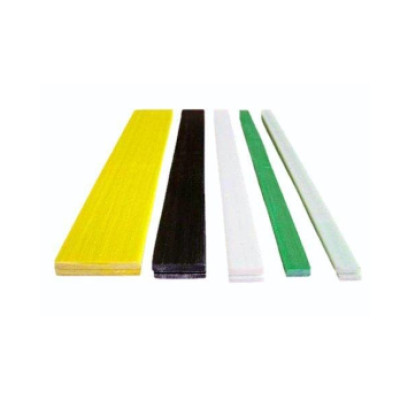

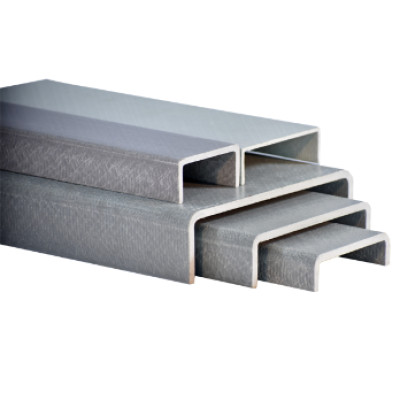

- Customizable Shapes and Sizes: Pultrusion allows for precise control over the profile’s shape, which can be customized to meet the specific requirements of architectural designs or structural needs.

- Flexibility and Impact Resistance: FRC pultruded profiles combine the flexibility of glass fibers with the toughness of concrete, making them more resistant to cracking and breaking under stress.

- Improved Aesthetic Options: The pultrusion process can create profiles with smooth, uniform surfaces, which can be finished to replicate other materials like stone or wood. This makes them ideal for architectural facades, decorative elements, and functional structures.

- Efficient Production: Pultrusion is a continuous manufacturing process, which makes it efficient for large-scale production. This results in cost-effective FRC profiles for both small and large projects

Applications of GRP Pultruded Profiles:

1. Architectural Panels and Cladding: Pultruded FRC profiles are used for creating modern facades, wall panels, and architectural cladding, often in large commercial and residential buildings.

2. Window and Door Frames: These profiles can be used for window frames or door surrounds, providing both strength and aesthetic appeal while reducing the need for heavy materials.

3. Custom Molding: Pultruded FRP can be used for creating customized moldings, cornices, and decorative elements, often used in both interior and exterior architectural features.

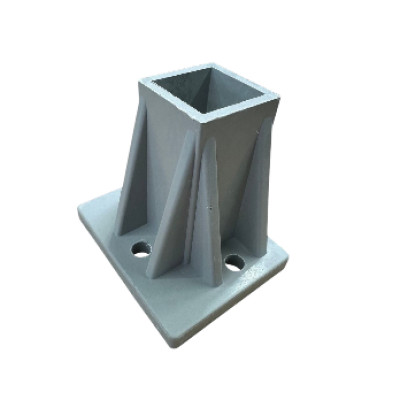

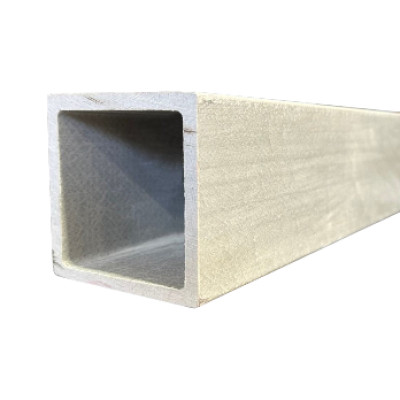

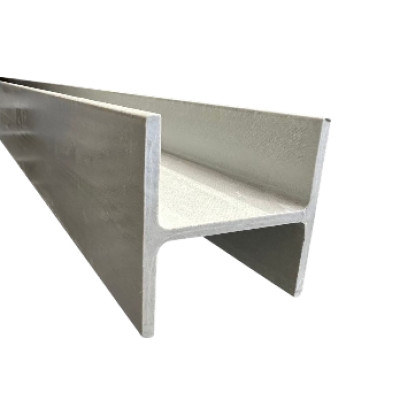

4. Structural Elements: They can be used in structural applications such as beams, columns, and reinforcement bars where high strength and resistance to environmental factors are required.

5. Marine and Coastal Structures: Due to their corrosion resistance, pultruded FRC profiles are ideal for use in coastal areas, marine environments, or locations exposed to harsh weather conditions.

6. Transportation Infrastructure: Pultruded FRC profiles are also used in the transportation industry, for applications like bridge elements, sound barriers, or protective casings

Benefits of Pultruded FRP Profiles over Traditional Methods:

- Lightweight and Easy to Handle: The combination of glass fibers and concrete offers a lighter alternative to solid concrete or metal profiles.

- Cost Efficiency: Pultrusion is a continuous and automated process that reduces labor costs and material waste.

- Enhanced Strength: The alignment of the glass fibers during pultrusion maximizes the strength of the profile in the direction of the fibers, resulting in a product that can handle both tensile and compressive forces effectively.

- Reduced Maintenance: Due to the corrosion resistance of glass fibers and the durability of concrete, FRC pultruded profiles require less maintenance compared to traditional metal or timber profiles

FRC pultruded profiles combine the best of glass fiber technology and concrete, offering a lightweight, durable, and customizable solution for a wide range of architectural and structural applications. Their unique properties make them ideal for both decorative and functional elements in modern construction projects