FRP Heavy Duty Platforms

FRP Heavy Duty Platforms

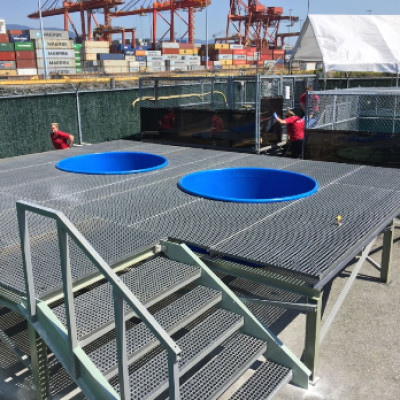

FRP (Fiberglass Reinforced Polymer – FRP) Heavy Duty Platforms are designed for use in demanding environments where strength, durability, and corrosion resistance are crucial. These platforms are typically used in industries such as chemical plants, offshore structures, power plants, water treatment facilities, and anywhere exposure to harsh conditions (e.g., chemicals, moisture, UV light, and salt) requires specialized materials.

- Anti-Slip Surface: Platforms have an anti-slip textured surface, often a diamond pattern, grit coating, or raised patterns that enhance traction, especially in wet or oily conditions.

- Edge Protection: Many heavy-duty platforms are designed with raised edges or toe boards to prevent tools or materials from falling off the edge.

- Guardrails/Handrails: Platforms often come with integrated guardrails or handrails that can be installed along the edges for safety.

- Ladder or Stairs Access: Platforms are often designed to be accessed via ladders or stairs, which can be incorporated into the platform structure.

- Load Indicators: Some platforms are equipped with load indicator markings or systems to ensure that the load is within safe limits.

- Corrosion Resistance: GFRP platforms are highly resistant to corrosion, making them ideal for use in chemical plants, marine environments, and wastewater treatment facilities, where exposure to chemicals, salts, and moisture is common.

- UV Resistance: GFRP materials are treated to be UV-resistant, ensuring that the platform will not degrade or lose its mechanical properties due to prolonged exposure to sunlight.

- Chemical Resistance: GFRP platforms can withstand exposure to a wide range of aggressive chemicals, including acids, alkalis, solvents, and oils, without deteriorating.

- Fire Resistance: GFRP platforms can be made fire-resistant by using fire-retardant resins and coatings. These platforms may meet Class 1 or Class A fire ratings depending on the resin choice and additional fireproofing treatments.

- Impact Resistance: GFRP is highly resistant to impact, which is beneficial in industrial environments where equipment or materials may be dropped.

- Minimal Maintenance: GFRP platforms require minimal maintenance because they do not corrode, rust, or degrade. Cleaning is typically done with mild detergent and water, and the platforms should be inspected periodically for structural integrity.

- Long Service Life: With proper care, GFRP platforms can last 20 to 30 years, or even longer, making them a cost-effective choice in the long term.

Applications:

- Chemical & Petrochemical Plants: Perfect for environments exposed to corrosive chemicals, vapors, and other harsh substances.

- Offshore Platforms: Ideal for offshore oil rigs and marine environments due to their corrosion and UV resistance.

- Water Treatment & Wastewater Plants: Commonly used in environments where water or chemicals are in constant contact with the platform.

- Industrial Equipment Access: Provides access to machinery and equipment in factories, refineries, and power plants.

- Renewable Energy: Used in wind farms, solar panel installations, and other renewable energy projects.

- Construction Sites: Ideal for temporary heavy-duty platforms in large-scale construction projects.