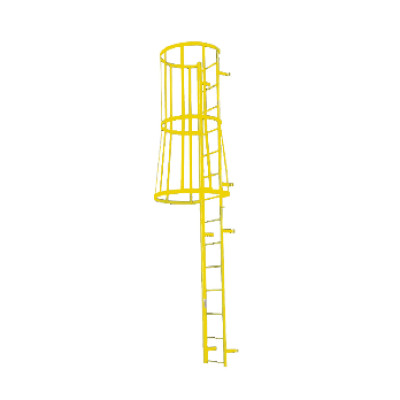

FRP Ladder

Fiberglass Reinforced Polymer FRP ladders are used in various industrial, commercial, and infrastructure settings, offering a lightweight, durable, and corrosion-resistant alternative to traditional metal or wooden ladders. They are particularly suitable for environments where exposure to chemicals, moisture, or extreme conditions makes traditional materials less practical.

- Anti-Slip: Rungs and side rails are designed to be slip-resistant, reducing the risk of accidents.

- Non-Conductive: FRP ladders are electrically non-conductive, making them ideal for use in electrical environments or in areas with high voltage risks.

- Corrosion Resistance: FRP ladders excel in environments exposed to corrosive materials, such as chemicals, saltwater, and moisture, making them ideal for use in marine, chemical plants, and wastewater treatment facilities.

- UV Resistance: The glass fiber and resin are often treated to be UV-resistant, ensuring that the ladder does not degrade when exposed to sunlight over time.

- Fire Resistance: FRP ladders can be designed to be fire-retardant by using specific resins or coatings. Fire-resistance ratings typically include Class 1 or Class A, meeting relevant fire safety standards.

- FRP ladders require minimal maintenance because they do not rust, corrode, or degrade due to exposure to chemicals, moisture, or UV light.

Applications:

- Industrial Settings: Used in factories, refineries, and power plants, particularly in environments where corrosion resistance is essential.

- Electrical Work: Ideal for use in electrical environments due to their non-conductive nature.

- Marine: Suitable for ships, offshore platforms, and docks where exposure to seawater is a concern.

- Chemical Plants: GFRP ladders are used in chemical processing plants where exposure to harsh chemicals and corrosive substances is common.

- Water Treatment Plants: Common in wastewater treatment plants and other facilities where water exposure is prevalent.